ePP/DS supports these scenarios in an ideal way. The basis in

ePP/DS is always a planning version.

The planning version contains the master and transaction data. A

distinction is made between an active planning version and

several possible inactive planning versions. As a rule, the

master and transaction data of the active planning version

(i.e., the live data) are copied into the inactive planning

versions, where they can be changed without affecting the active

planning version. Since inactive planning versions are

self-sufficient, planning results cannot be copied back to the

active version. The corresponding changes to the master and

transaction data must be repeated.

Within a planning version, so-called simulation

versions

can be created. Simulation versions play a role especially in

capacity planning/detailed scheduling in SAP.

When one enters an interactive planning tool (detailed

scheduling table, resource planning table, product planning

table), the system automatically creates a simulation version.

Within this, the planner can carry out his planning; the result

of the planning is simulative as long as it is not transferred

to the active planning version.

In the event that the planner does not want to transfer his

result directly into the active planning version, it is possible

to save the simulation version. This is temporarily parked and

can be displayed, edited or transferred directly to the active

planning version if required. Several simulation versions can

also be created and compared with each other, e.g. via the plan

monitor. In doing so, the data flow from the planning version to

the simulation version is open, i.e. changes in the active

planning version are immediately transferred to the respective

simulation versions so that there is no major discrepancy

between the live system and the simulation version. This also

ensures that the live data is not overwritten in an undesirable

way, when the simulation version is restored to the active

planning version.

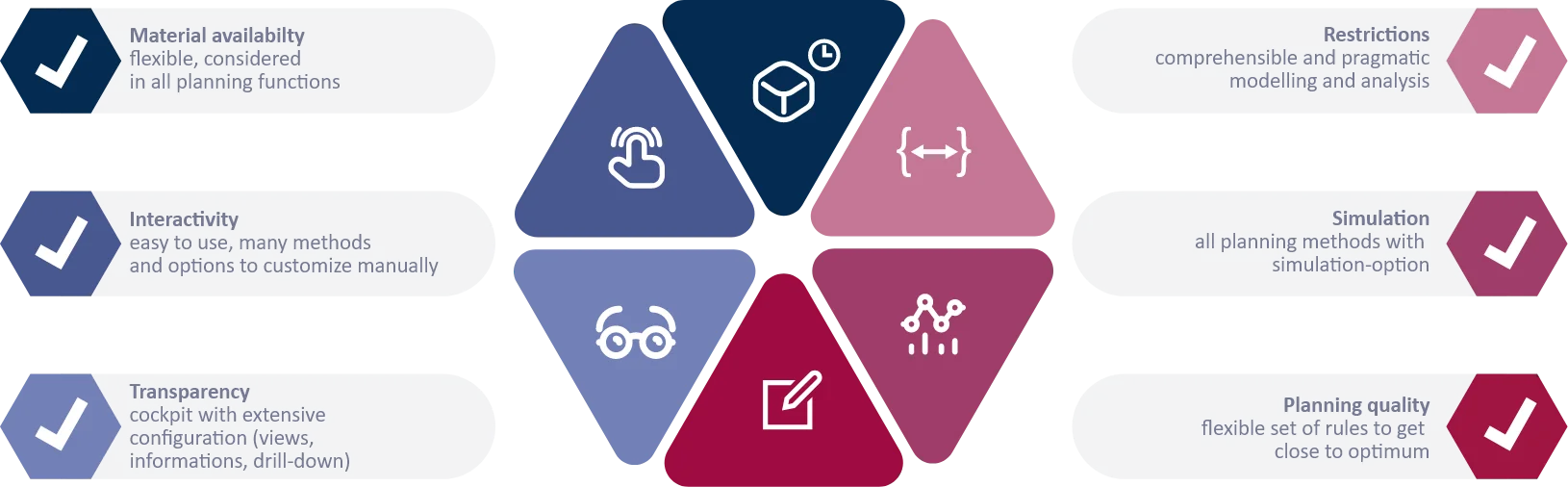

ITeanova supports customers in creating and implementing such

what-if scenarios (which simulations make business sense) and

solution variants. Care is taken to ensure that the principles

of automated planning and manual intervention or (manual) human

decision making are ideally combined.