Features of an Advanced Planning System (APS)

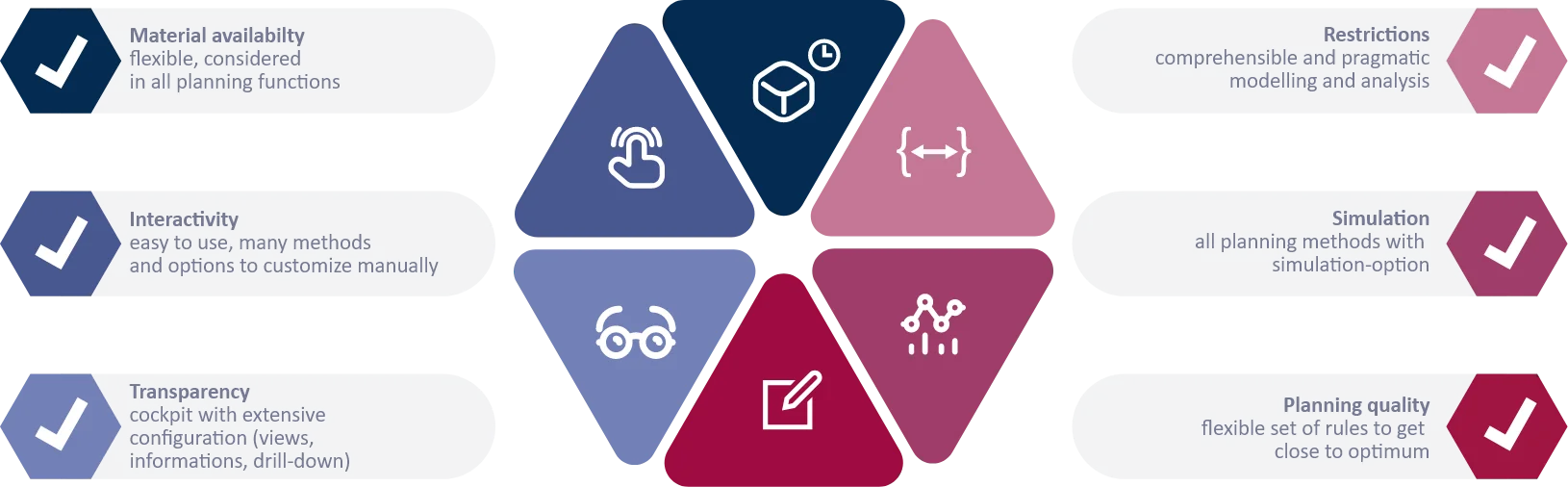

An APS system enables comprehensive planning abilities that encompass various planning criteria. APS systems differ from simple planning software products mainly in the following features:

- Planning across the entire supply chain (also called "multi-level planning") can include all factors of the supply chain as planning components: from purchasing to delivery

- Using a combination of the following components:

- Ensuring material availability across the entire supply chain

- Planning against restrictions (especially against limited production resources)

- Planning against rules, which guarantees a high planning quality in addition to compliance with the restrictions (e.g. short set-up times, short storage times, use of the most efficient resources)

APS systems cover all planning horizons, from the very short-term (the next few days) to a long-term horizon (several months). To achieve this, especially in the long-term area, an APS tool must also be able to perform simulations: Production plans are drawn up and compared on the basis of hypothetical assumptions (e.g. development of orders from key customers, expansion of machinery, hiring of additional employees, relocation of production to other sites).