PPC Sequencer

The basis for efficient and transparent production is a detailed and feasible production plan.

The basis for efficient and transparent production is a detailed and feasible production plan.

In detailed planning, which is normally used in the short-term horizon, the relevant target variables are as follows:

Detailed planning encompasses the aspects of the optimal sequencing of operations or orders and the detailed production capacity levelling within a short-term horizon.

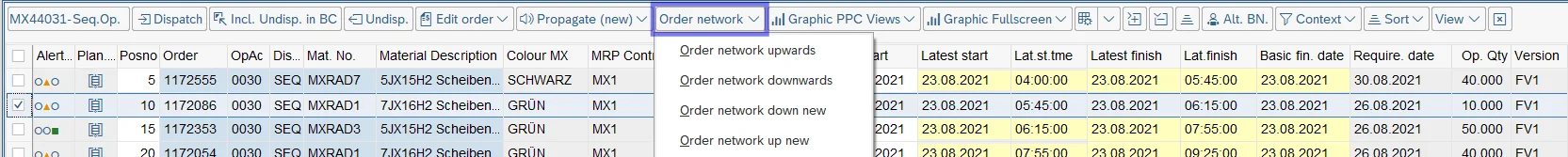

Multi-level order network with pegging according to ATP logic for a material

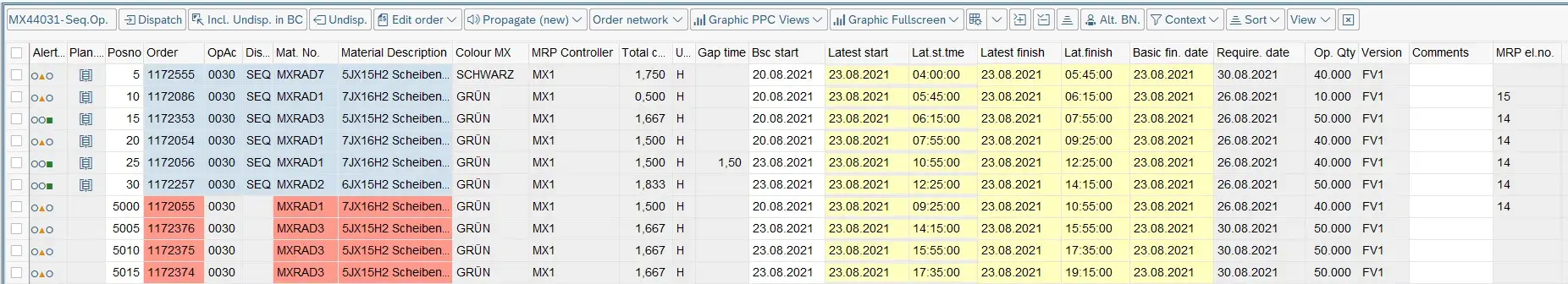

Detailed planning overview: Scheduling/sequencing of production and planned orders with relevant detailed information, such as due date/requirement date, product characteristics (colour), material, duration and quantity.

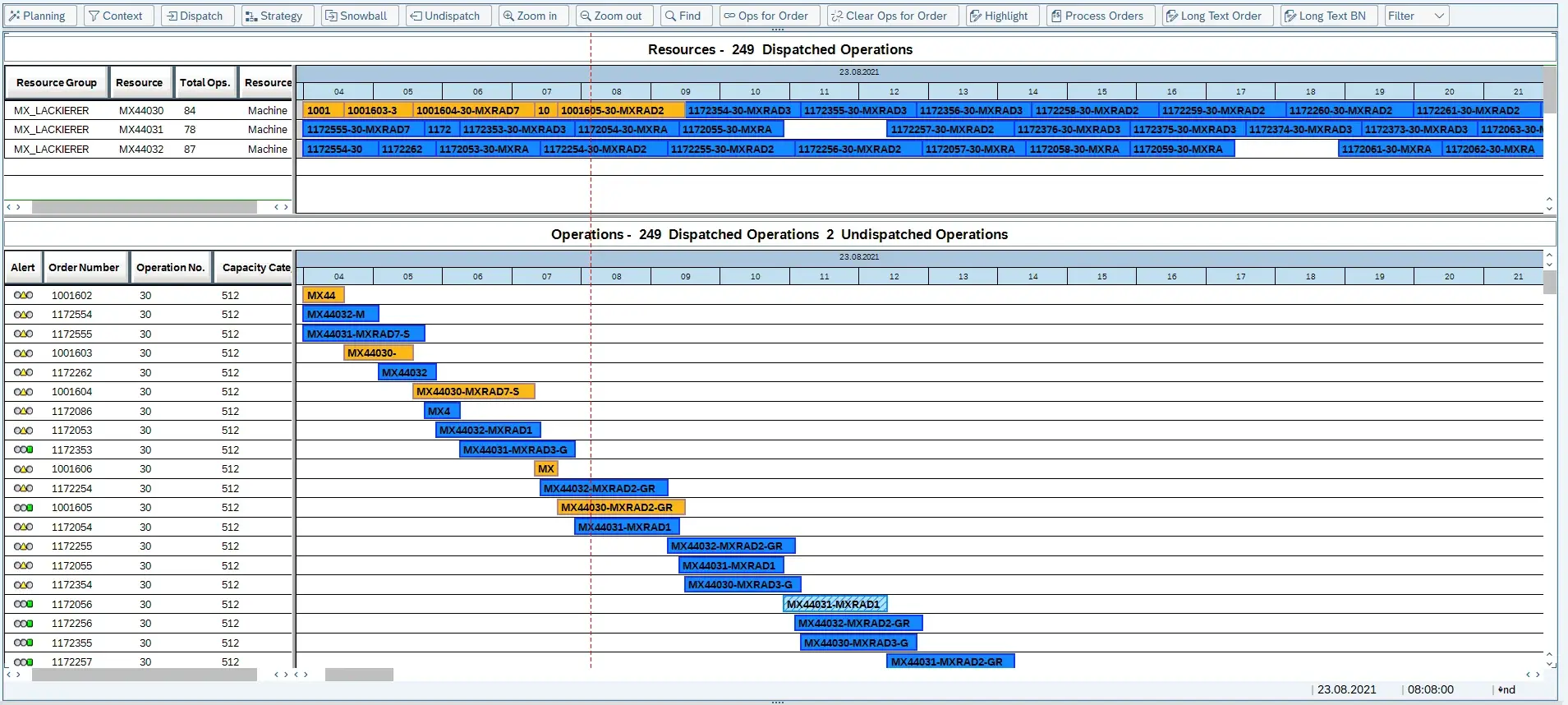

Detailed planning overview: Graphical planning board

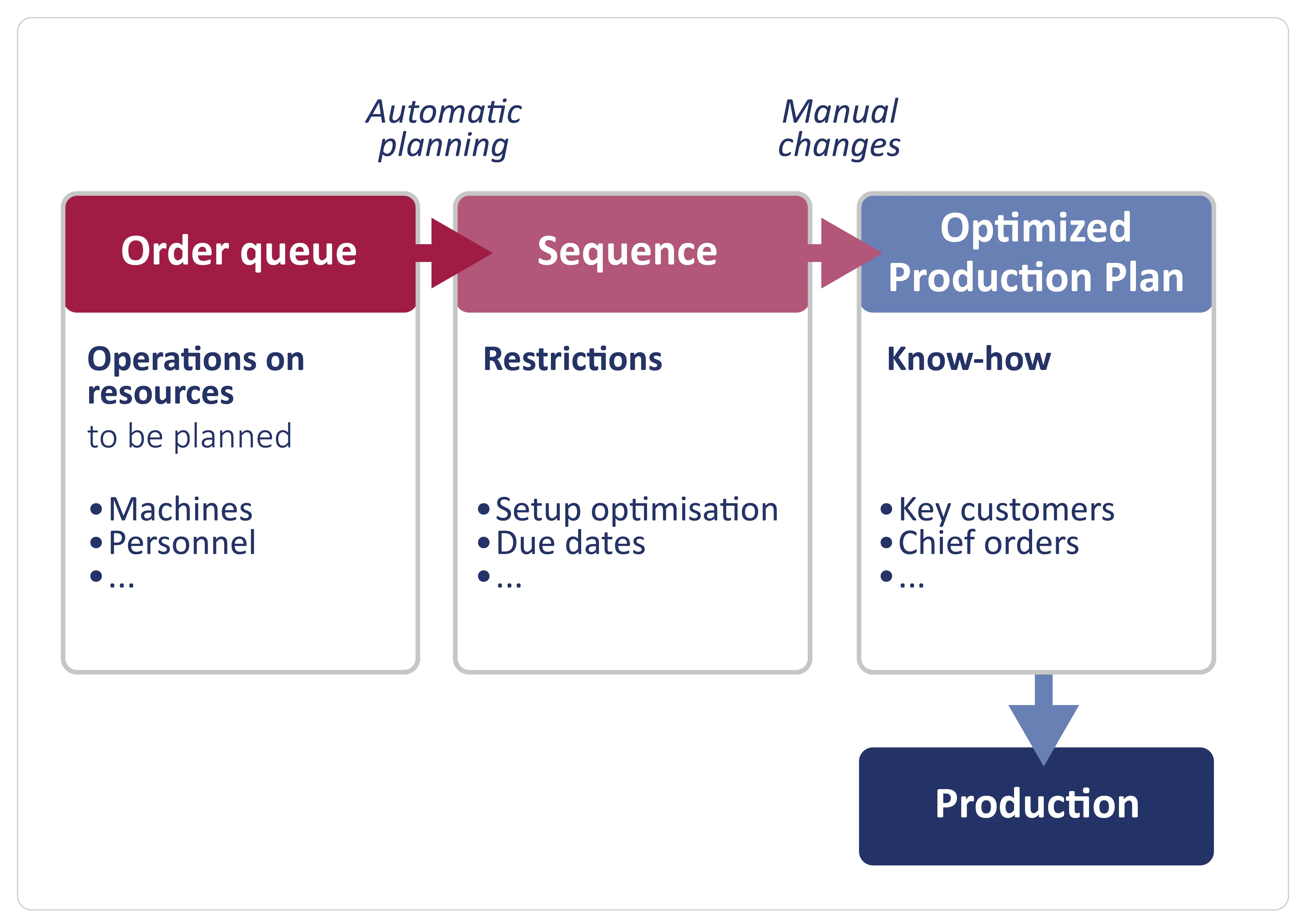

Detailed planning can be carried out completely in the background or online using the corresponding function code in the PPC Sequencer.

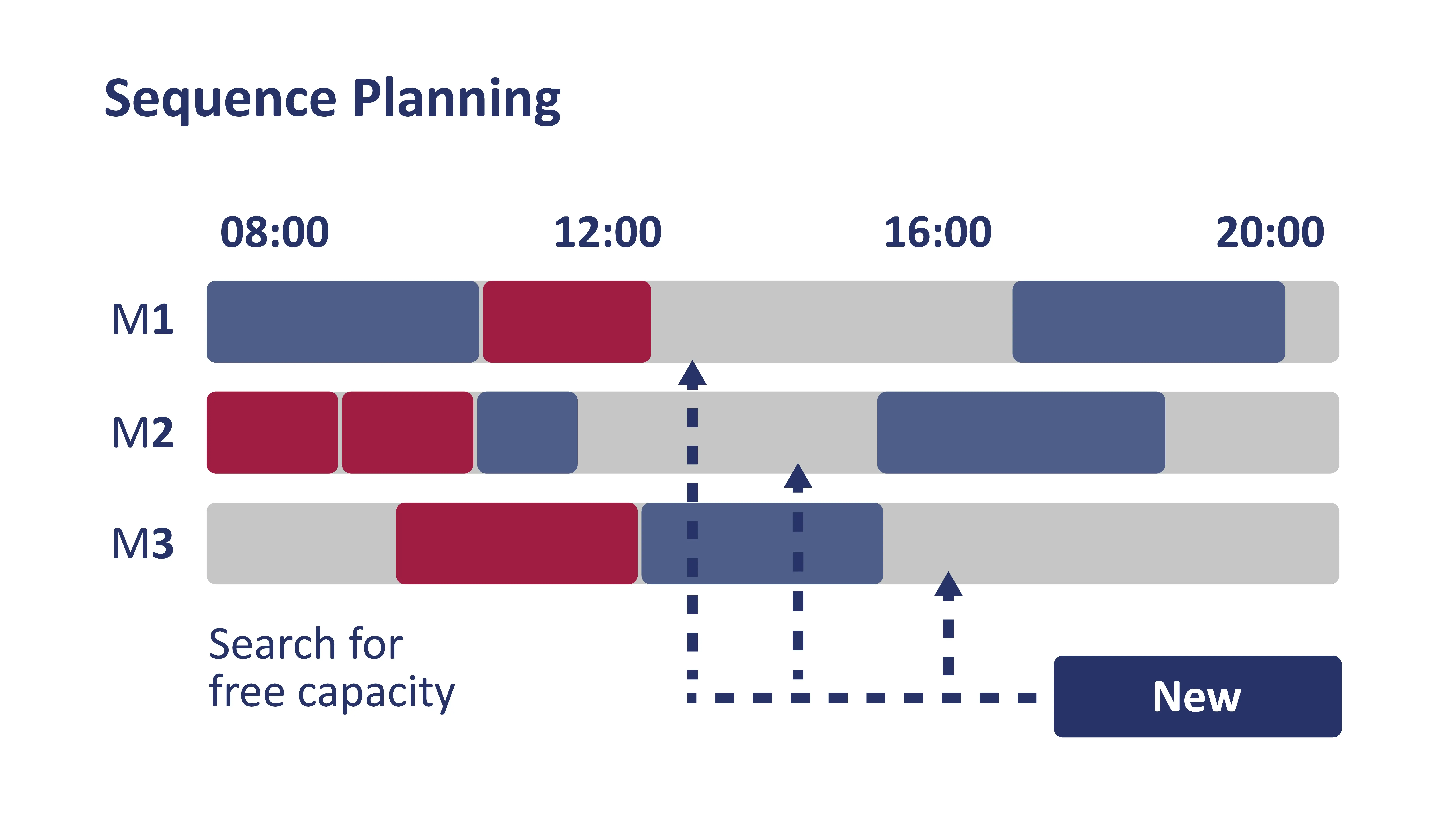

Manual planning is possible as well. In this case, the responsible is assisted by the tool for an optimal realization of his or her decisions:

An advantage of the PPC Sequencer is the combination of automatic and manual detailed planning. The automatic scheduling offers a proposal for the planning allocation with all its consequences (derived indicators, exceptions). Afterwards, it is possible to fine-tune the results manually.

Process of semi-automatic detailed planning

Jump to super-/subordinate production levels for displaying the components or causing requirements (e.g. customer orders)

Get our ready-to-implement Production Planning Cockpit and its modules to open up new possibilities in your production planning.

Learn moreLink to take you to the above page where you can learn more.We know the SAP Standard by heart and can help you to get the most out of it for your individual purposes!

Learn moreLink to take you to the above page where you can learn more.With our experience we can bring your SAP fundament to a higher level, enhancing your business process with individual solutions.

Learn moreLink to take you to the above page where you can learn more.