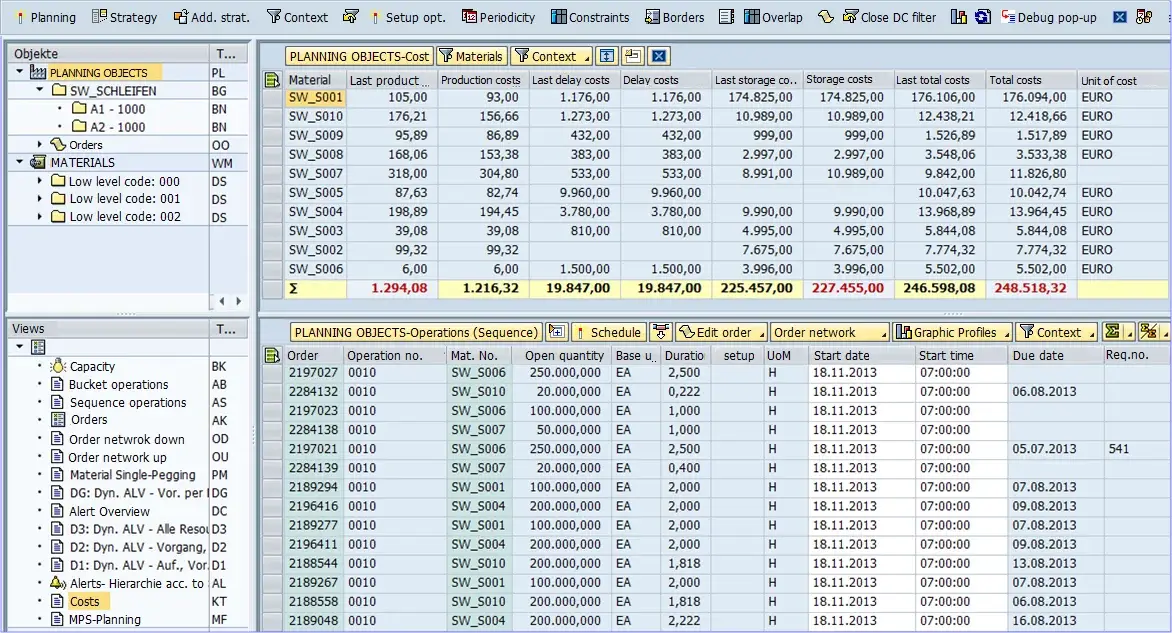

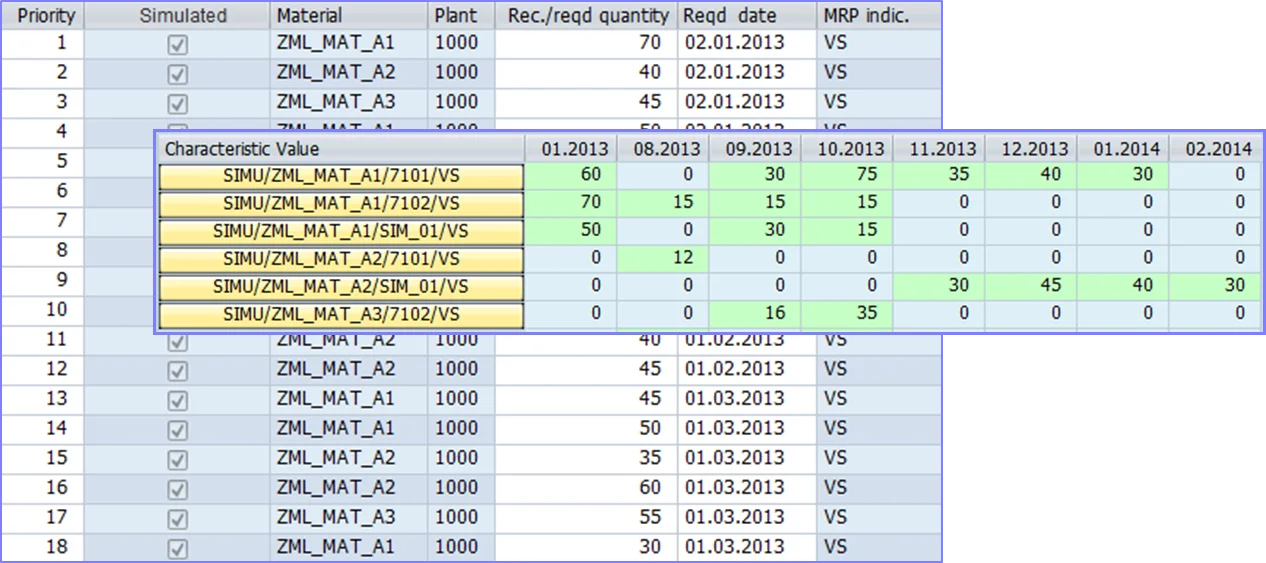

PPC Simulation Cost Monitor

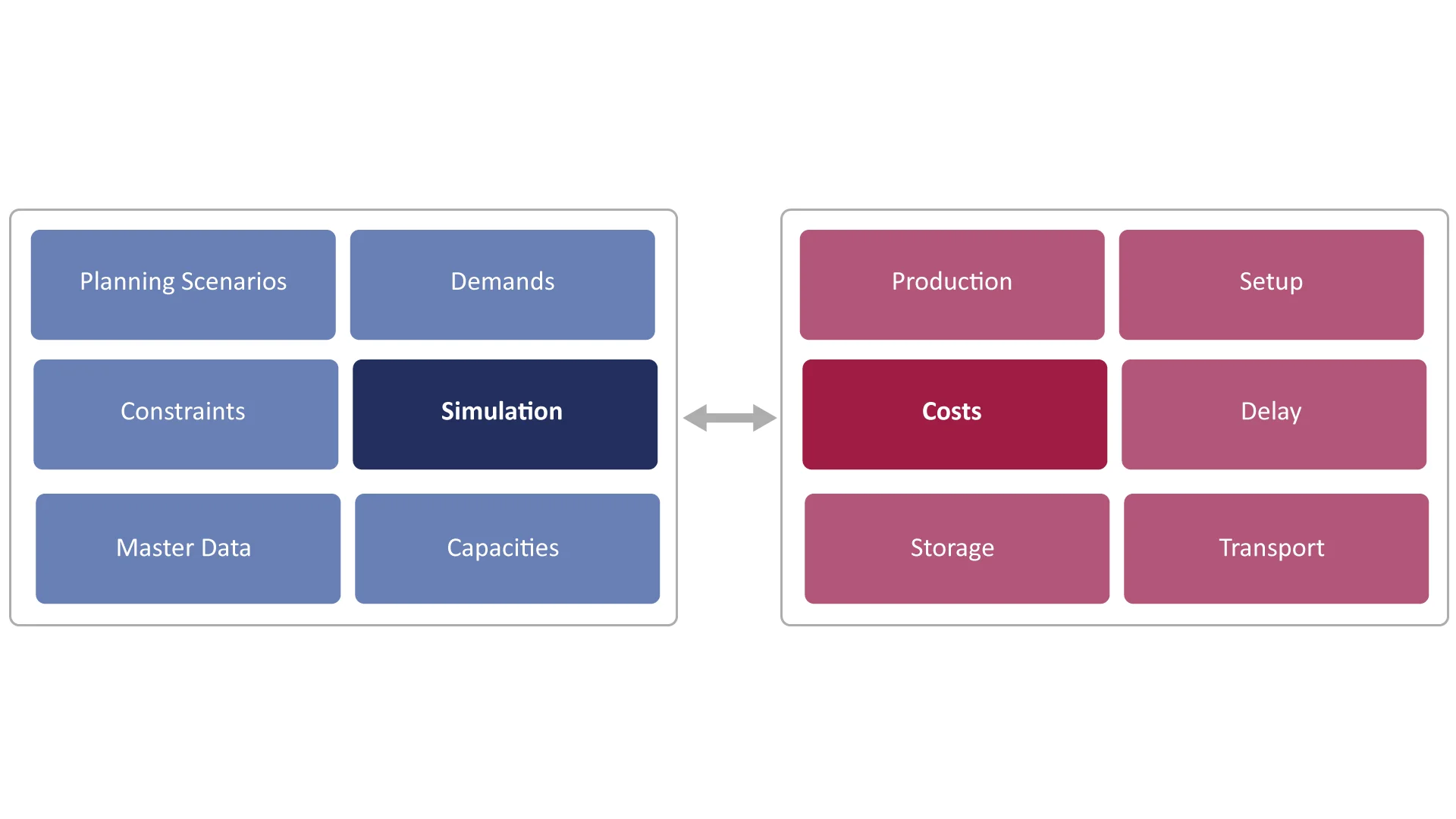

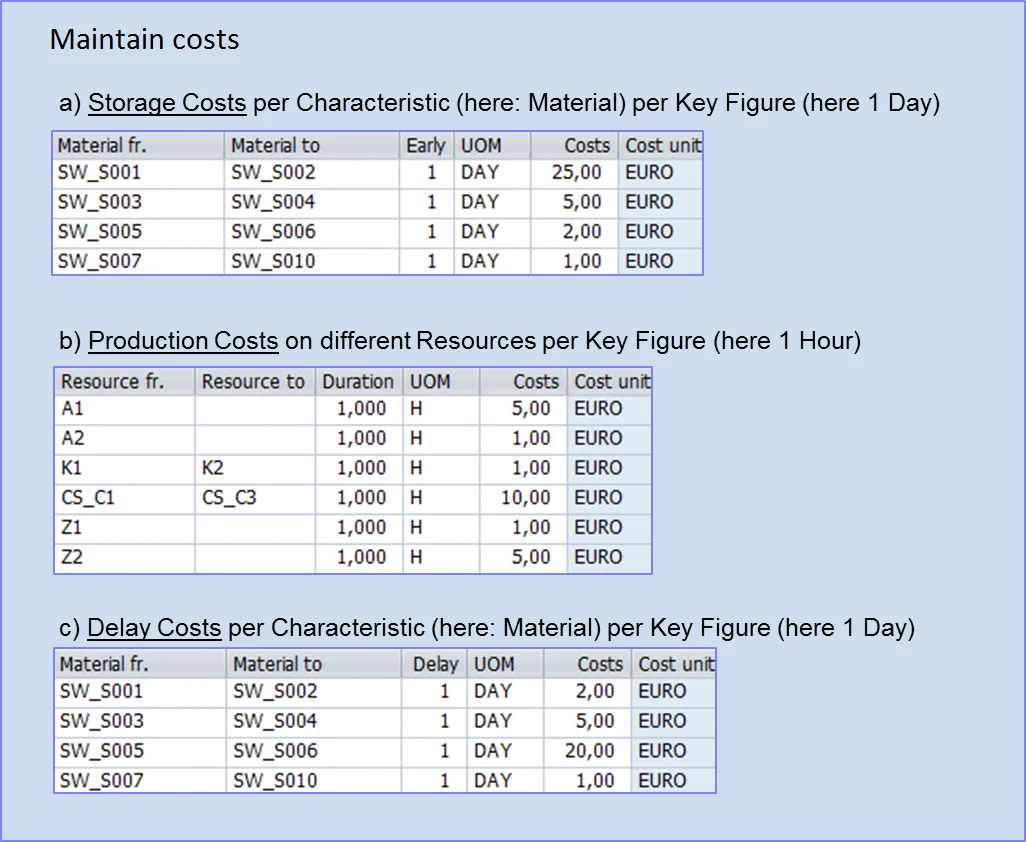

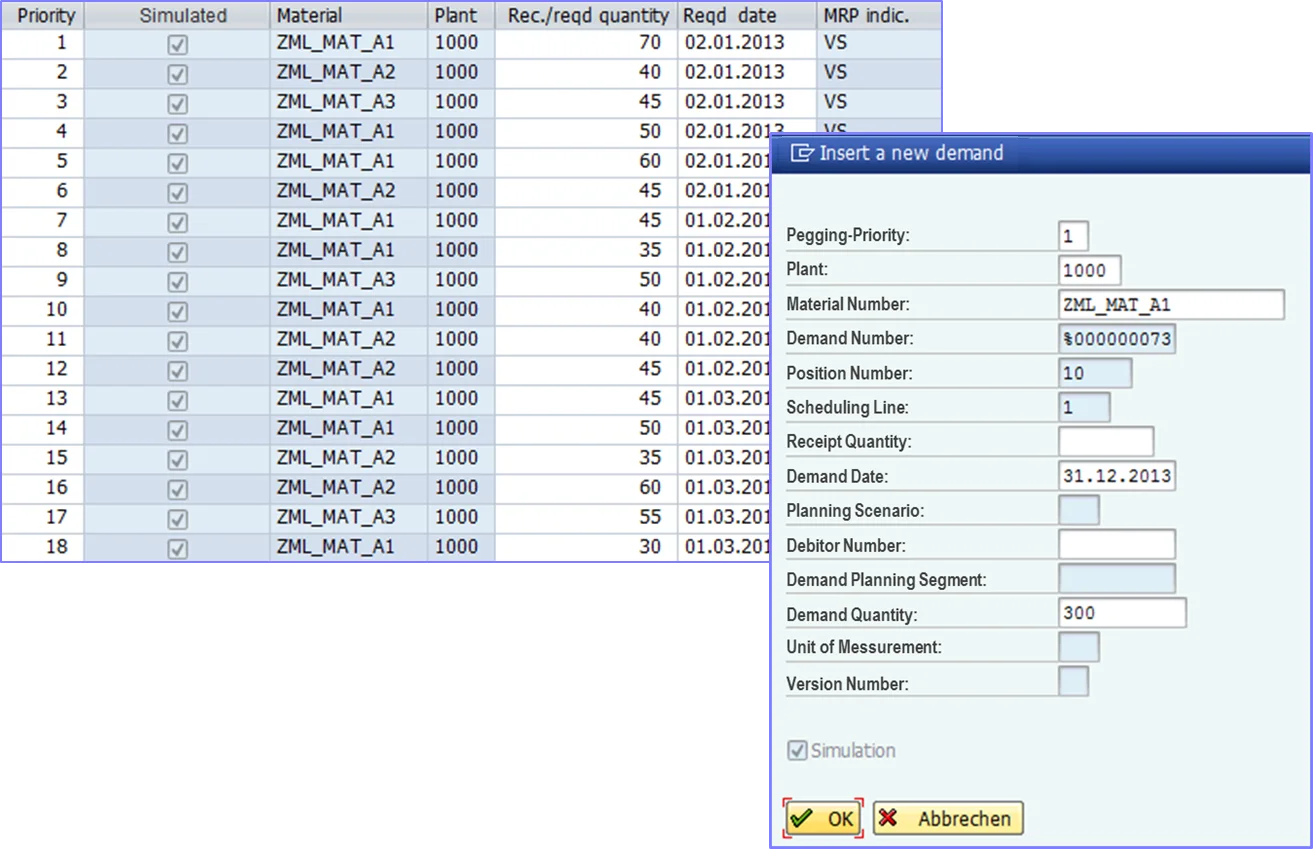

Costs play a major role in all manufacturing and service companies. There are always several ways to produce a range of products or to fulfil a production plan. In order to run through these options and compare the costs, the best way is to simulate and compare different variants.