Constraints planning

In an Advanced Planning System (APS) it is crucial to be able to depict the restrictions that often occur in reality in an understandable and effective way.

For example, machines and personnel cannot work an infinite number of hours, not all machines and personnel can handle all work processes, storage and delivery capacities are scarce, and the quantity throughput in production is limited.

Restrictions in planning

- machine availability

- runtimes

- multi-use resource

- not all personnel can operate with all machines and execute all operations

- e.g. catalyst, pressing tool,

- extrusion tool

- in sequence

- with overlap

- parallel

- buffers

- max. WIP: restricted space

- min. WIP: guarantee material provision

- provision

- scheduling in order groups

- group via SD criteria

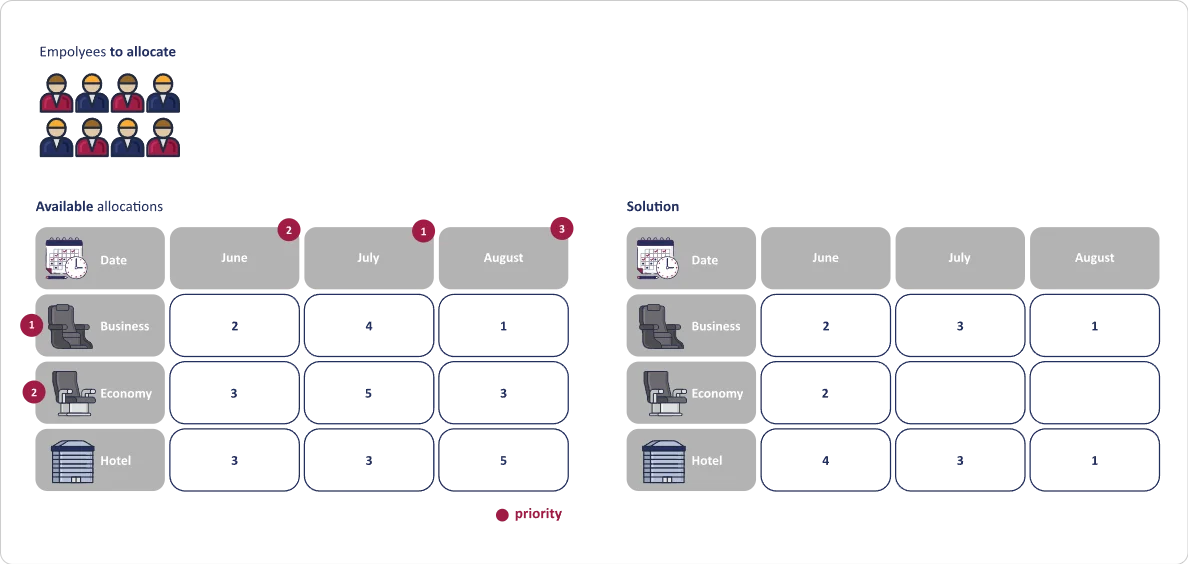

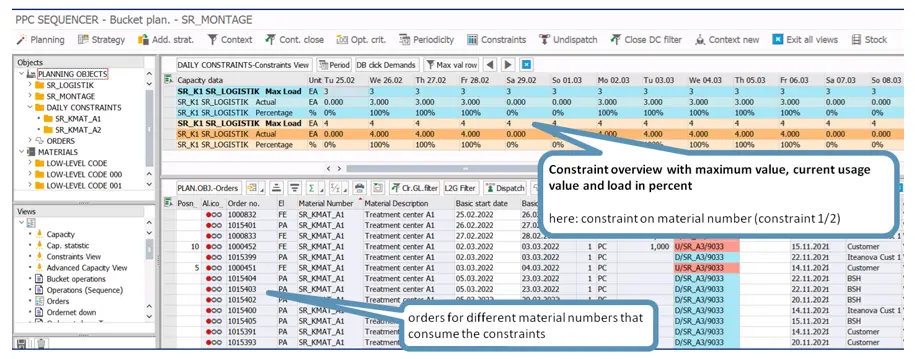

In SAP, these restrictions are often modelled using work centers and capacity categories. However, this representation can also be too complex and unsuitable for use in algorithms/heuristics. For this reason, ITeanova has developed a method of mapping some restrictions using product allocation. The term for this in the Production Planning Cockpit "PPC" is "constraints".