PPC heuristics

ITeanova’s heuristics (and heuristics in general) aim to achieve a very good (almost optimal) planning result through a pragmatic planning approach that has been proven in practice. They are largely based on industry-specific approaches to finding solutions (e.g. sequencing based on the colours used in the printing industry). The PPC heuristics functionality can be flexibly configured and adapted to new scenarios. Special customer-specific requirements can be added at strategically important points in coding without modification (user exit).

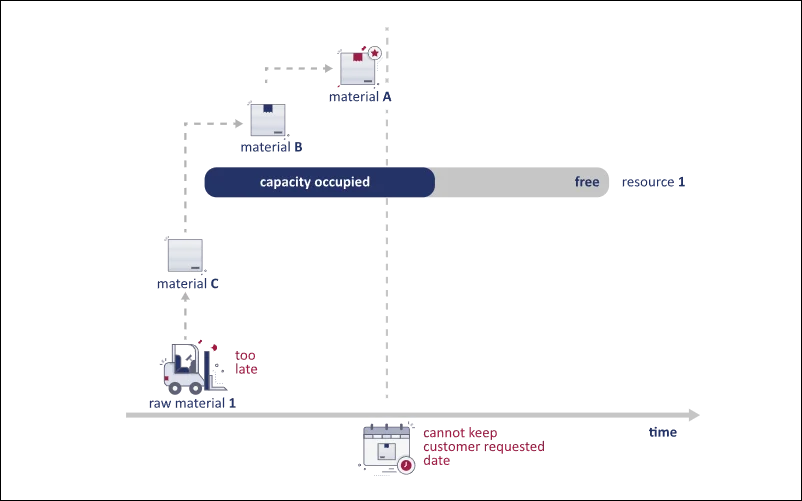

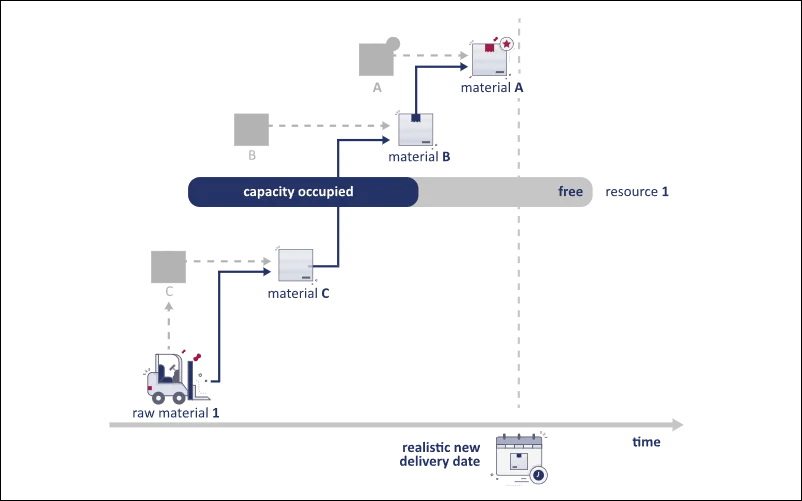

The decisive factor for an efficient and above all feasible production plan is the simultaneous consideration of the two most important factors:

Material availability

- Raw materials must be available in time for production.

- Assemblies must be manufactured and processed on time.

- The customer should receive his ordered products on the agreed date.

Capacity planning

- Machines, personnel and other bottlenecks must not be overloaded, but an appropriate workload must be ensured.

- Production rules must be observed, e.g. the sequence of operations.

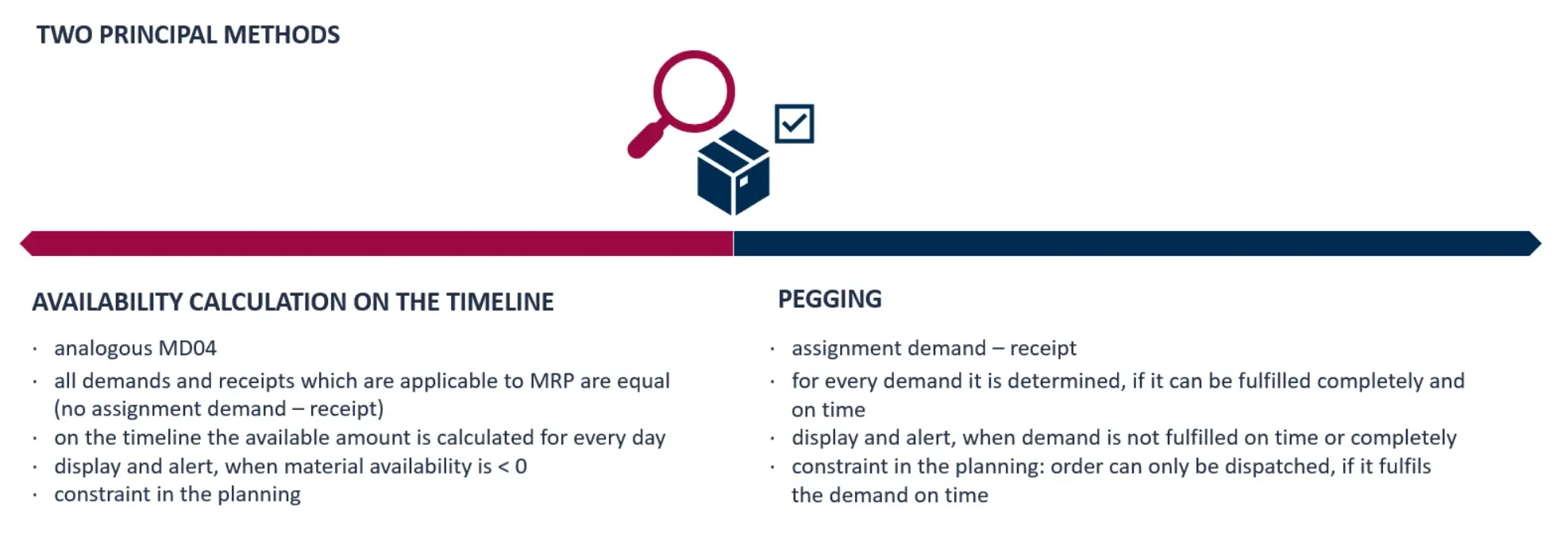

Material availability can be determined in different ways

In addition to material availability, there may be other restrictions that must be taken into account for a feasible production plan: